INNOVATE

The Mazda3 Hatchback: a unique concept

Creating a stunning concept car is one thing, but achieving the same beauty on a production car is a harder task. Mazda Stories learns how the Mazda3 was crafted to ensure it matched the appeal of the original Kai Concept car.

Mazda’s meticulous attention to detail is second to none, thanks to its Kodo Soul of Motion design language. The philosophy is born out of the strong belief that creating an ultimate form of beauty via the seasoned hands of Takumi craftsmen will breathe life into the car. Craftsmanship may be a term that is used a little too casually and frequently in marketing, but throughout its history Mazda has stayed true to the exact meaning of the word. The Mazda3 is the latest embodiment.

“The Mazda3 Hatchback is based on the Kai Concept model we unveiled at the Tokyo Motor Show in 2017,” says Yasutake Tsuchida, Chief Designer of the Mazda3. “Normally, making a mass production model from its concept means a series of compromises. But that’s not the way we work. Craft is the key and we work closely with everyone involved, from modelers to engineers to production members, so as to achieve truly artful form. This is why the production model retains the same design ethos and emotional glamour as its original concept.”

While some concept cars are designed only to illuminate motor shows, the Kai was Mazda’s ideal vision of a hatchback, and the various divisions in the company were determined to make it happen together. Perhaps the key to achieving this was the aspiration to true craftsmanship and realising the ultimate beauty in the car. Speak to anyone in the factories, and they’ll confirm Mazda’s way. Manager Kenji Anraku, who led a team of master mold makers working on the car’s exterior panels, explains: “We discuss and sometimes even argue with designers, but that’s all for the sake of taking the design to the next level. The slightest margin of error is not permitted here.”

Toshitaka Matsui, Staff Manager of the manufacturing engineering team at the Hofu plant in Japan, agrees. He says: “It was obvious that the transition from the concept to the production model would prove challenging as the former was designed free of [manufacturing] regulations and production requirements. But we fully supported the Chief Designer in realising his vision. If we don’t have skill and expertise to make it happen, we would just innovate to overcome the challenges.” Of all the Mazda3’s technological and aesthetic achievements, the side panels, devoid of sharp character lines—a design cue popular in vehicle design—are an element of particular beauty. They’re a great example of the lengths Mazda went to when crafting the car.

“Creating a simple yet strong, artful form is the next step forward for Kodo design,” says Tsuchida. “Before we reached this stage, we had continuously added design elements to try to give a more energetic form to the cars. But with this model, our focus shifted to ‘less is more’.” This was easier said than done. Once a clay model was made, the design team scanned it in 3D to create its digital data and trialled making side panel prototypes. Yet, to Tsuchida’s astonishment, these were lacking all the artful elements the original clay model was equipped with. Tsuchida recalls: “It was just one smooth surface, but lacked a soul the modelers had meticulously put into the shapes.”

Investigations revealed that while scanning the clay model the computers would detect “inconsistencies” that human hands had made on the surfaces and opt to smooth the surfaces. But, Tsuchida says, it is these inconsistencies that give life, soul and energy to vehicle design. “Because it’s hand-made, a clay model naturally has uneven surfaces and warped lines. They’re there with the intent of the modelers, but the computers can’t understand it,” Tsuchida says. “At that point, we went back to the clay model to see how different the prototypes were compared to the hand-made form. We went back and forth between the two so many times to recreate the Takumi quality of the clay model in the digital data, too.”

It was an intensive and time-consuming process, but Tsuchida and his team never cut corners. And more than a year and a half later, they arrived at the ideal form, which we can now appreciate first-hand. In recalling this, he smiles, saying: “We’re so old school!” But this is the exact reason Mazda can call its cars a product of true craftsmanship, and the end result is impressive. The wavy contours on the side panels give the appearance of lean muscles waiting to unleash great power. At the same time, beautiful reflections on the panel convey Zen-like tranquility.

“Normally, making a mass production model from its concept means a series of compromises. But that’s not the way we work.”

Yasutake Tsuchida, Chief Designer

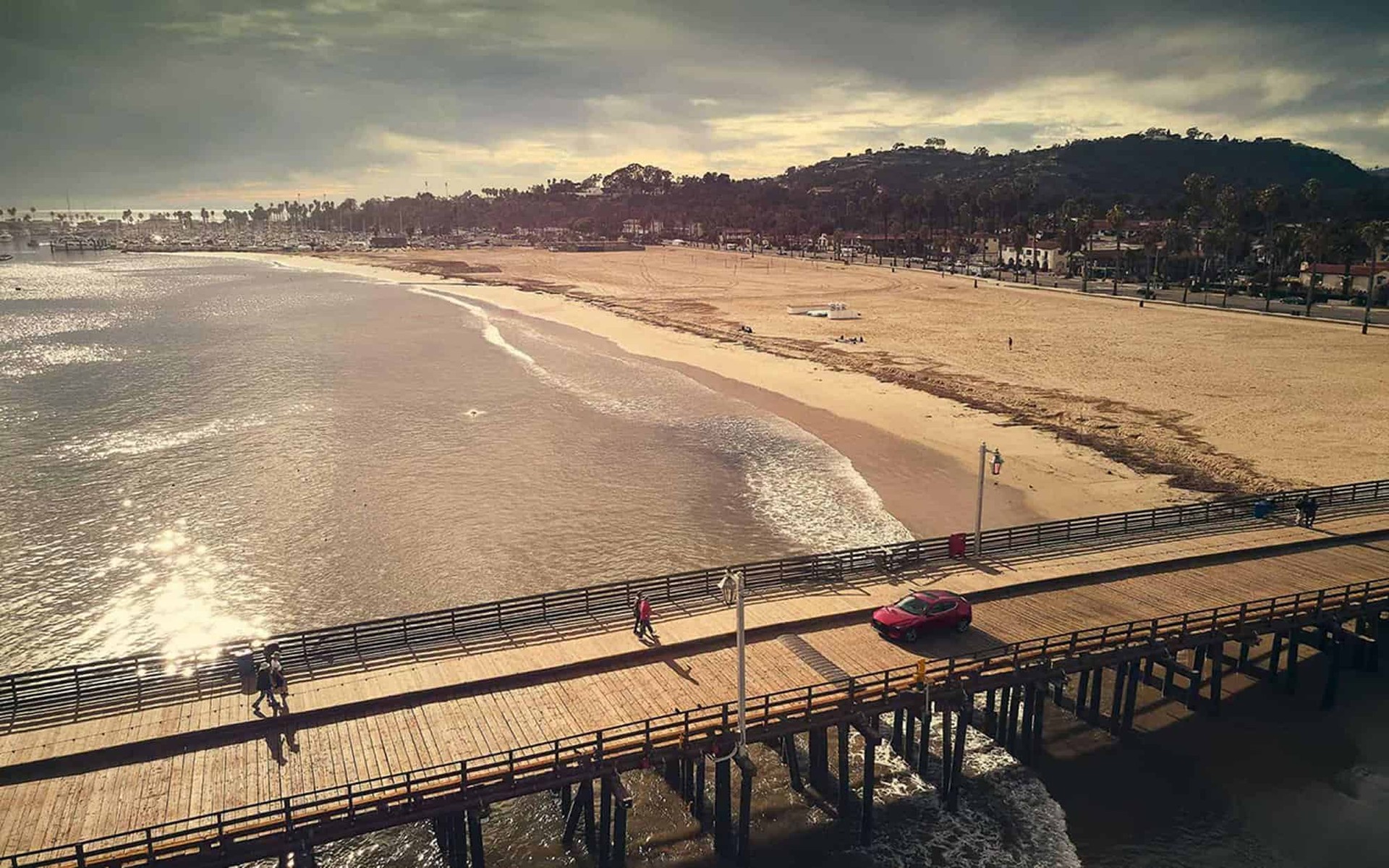

“The shapes and colours of the reflections change depending on where the car is and the time of day. The driver can appreciate the car more this way and their love of it deepens further,” Tsuchida says. And as with any craft, nothing tops long-lasting love.

Words Shogo Hagiwara

find out more

True craftsmanship

Discover Mazda’s award-winning hatchback